- Raw material Inspection

- Die casting Inspection

- Best Powder Painting

- Export carton

Strict Quality Control In Each Process

With highly skilled and detail-focused professionals with many years experience providing LED services. Excel at ensuring the highest attention to detail excellence while maximizing productivity and efficiency. OEM Designing Aluminum Die Casting LED Light housing Factory, With A Mission Make LED Products More Innovative, High Heat Dissipation, Long-Life Time Easy To Install And Low Cost For Customer Everywhere Along Our Global Markets.

Raw material Aluminum Ingot Quality Inspection

Each raw material aluminum back, we must QC very details in kind, Testing reports indicators all Elemental content,SI,FE,CU,MN,ME,CN,PB etc, ensure the highest attention to excellence while maximizing Qualified raw materials.

Die casting Quality Inspection

Always use right Weight Ton Machine to produce match size die casting housing, surface Bubbles, deformations, cracks, pits all will be Selected to Re-produce, Grinding,Sanding, Polish, that all Fine processing to Optimizing product quality again to perfectly.

Best Powder To Spray

Choose the best imported powder, Exquisite workmanship to painting powder, During Guarantee not affected heat sink dissipation and do best thickness 0.8-1.0mm, Outdoor Salt spray test over 500-1000hrs , make our die casting housing Warranty period 6-8years when you use.

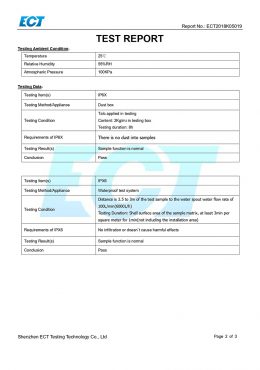

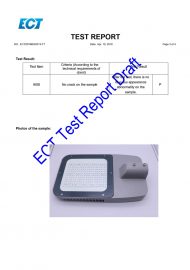

Finished Lighting LEDs, Old Testing

HIGH QULAITY LUMILED LED technology is applied for high efficiency, Optical and electrical assembly meets dust and moisture rating of IP66 per IEC60529, and ranking IK08 per EN62262, Brand power supplier choose ensure long life and protection from the environment.